PETG Second Processing Failures: Troubleshooting and Solutions

时间:2025-03-06 23:50:16 分类:行业资讯 访问量:589

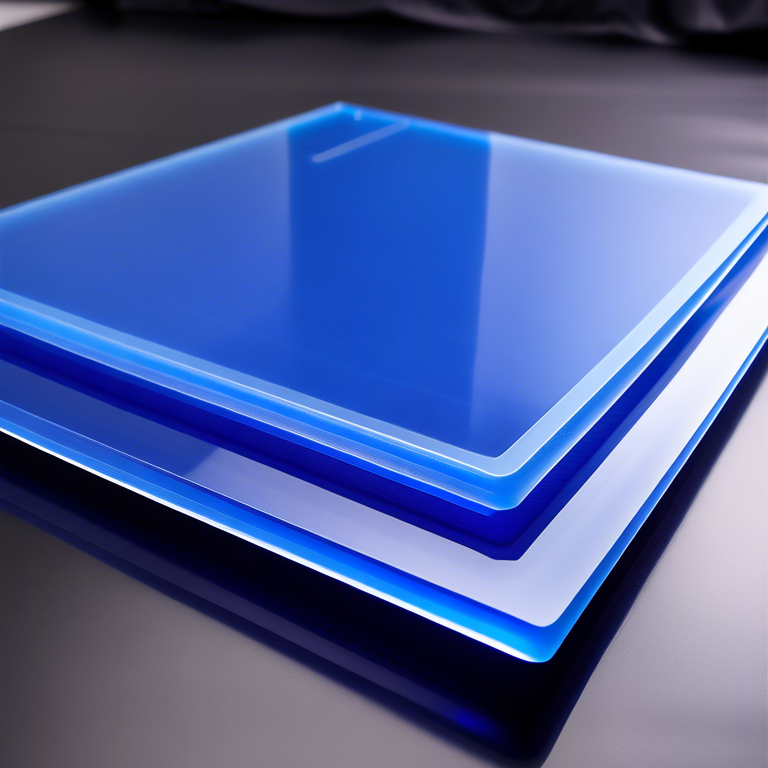

Understanding PETG and Its Properties

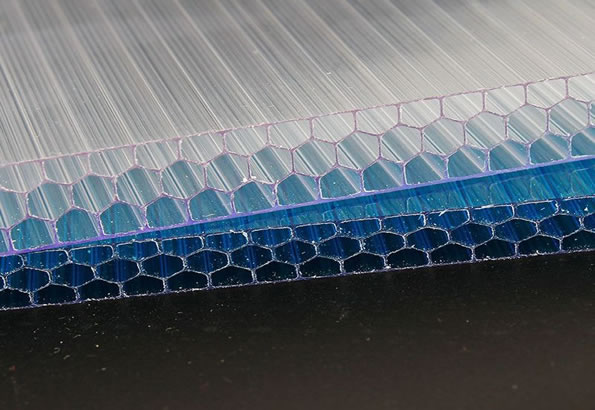

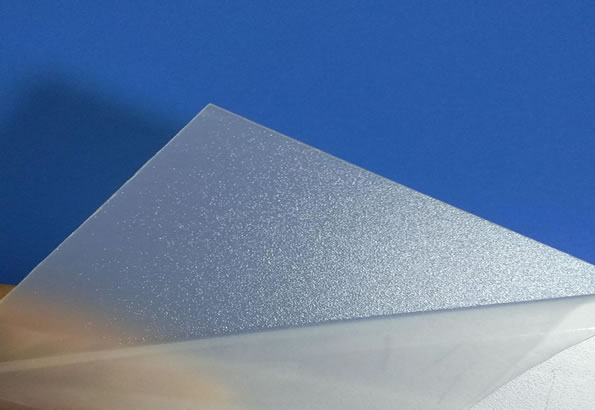

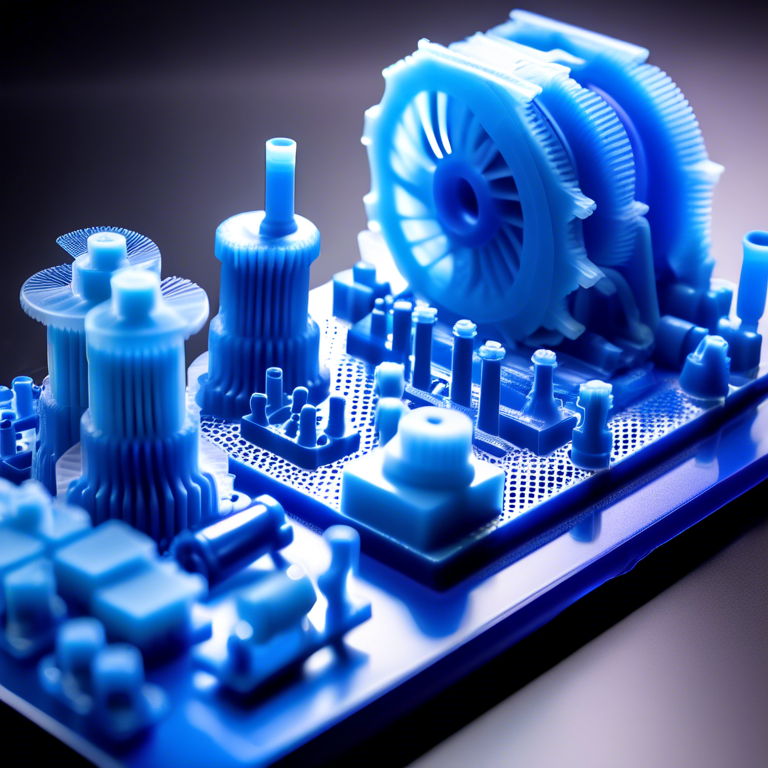

PETG, a thermoplastic polyester, offers a unique balance of clarity, impact strength, and ease of use, making it a favored material in various industries. Despite its advantages, PETG's sensitivity to processing conditions can lead to challenges during secondary operations, such as 3D printing, thermoforming, or machining. Understanding its thermal behavior, mechanical properties, and environmental stress factors is pivotal in mitigating breakage risks during subsequent processes.

Why PETG Products May Break During Secondary Processing

Several factors contribute to the vulnerability of PETG during a second round of processing. Thermal degradation, improper handling, and environmental stresses can compromise its integrity. Thermal degradation, for instance, occurs when PETG is subjected to temperatures beyond its heat deflection threshold, leading to molecular breakdown and brittleness. Additionally, environmental factors like humidity and exposure to certain chemicals can further affect PETG's performance.

Optimizing Processing Conditions for PETG

Adjusting processing parameters is key to preventing PETG products from breaking. This includes carefully controlling temperature settings, cooling rates, and handling procedures. Maintaining temperature within PETG's ideal processing range prevents thermal degradation. Moreover, ensuring gradual cooling can minimize internal stresses that predispose the material to fractures. Practicing meticulous handling to avoid physical damages during post-processing steps is also crucial.

Troubleshooting Common Issues in PETG Second Processing

Addressing common issues requires a systematic approach. Start by evaluating the processing environment—temperature, humidity, and cleanliness—to rule out external stress factors. If breakage persists, inspect the material for signs of degradation or contamination that may have occurred prior to the second processing. Implementing a thorough inspection regime can help identify and rectify these issues promptly, ensuring the material's integrity.

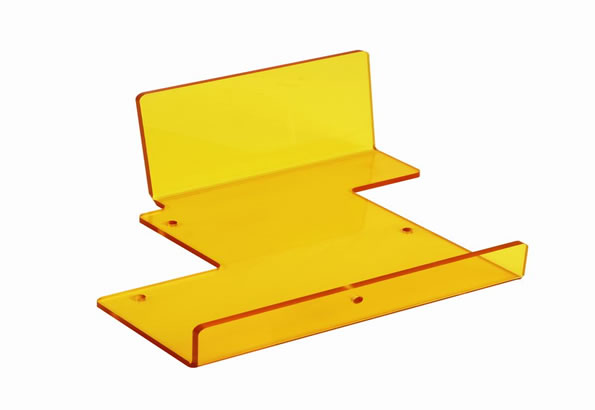

Implementing Best Practices for Successful PETG Processing

Successfully processing PETG on a second occasion demands adherence to best practices. These include pre-conditioning the material to stabilize its properties, carefully selecting compatible additives or coatings, and employing protective measures against environmental stresses. Emphasizing quality control throughout the processing chain maximizes the likelihood of achieving desired outcomes without material failure.

In conclusion, while PETG's breakage during secondary processing presents challenges, understanding its properties and optimizing processing conditions can significantly mitigate these issues. By addressing thermal and environmental stress factors, implementing systematic troubleshooting, and adhering to best processing practices, manufacturers and hobbyists can improve the resilience and performance of PETG products in secondary applications.文章名称:PETG Second Processing Failures: Troubleshooting and Solutions

文章链接:http://www.hbbxghs.com/xuancheng/list_16/317.html

本站资源仅供个人学习交流,请于下载后24小时内删除,不允许用于商业用途,否则法律问题自行承担。

上一篇:亚克力加工深度,亚克力深度加工